The measurement of temperature is essential in many industrial processes for production efficiency and quality control. Different types of temperature sensors are used in industries for temperature measurement, including thermocouples and RTDs (Resistance Temperature Detectors). RTDs offer several advantages over thermocouples in terms of accuracy, rangeability, and linearity. This article will discuss the details of RTDs and their applications.

RTD Principle:

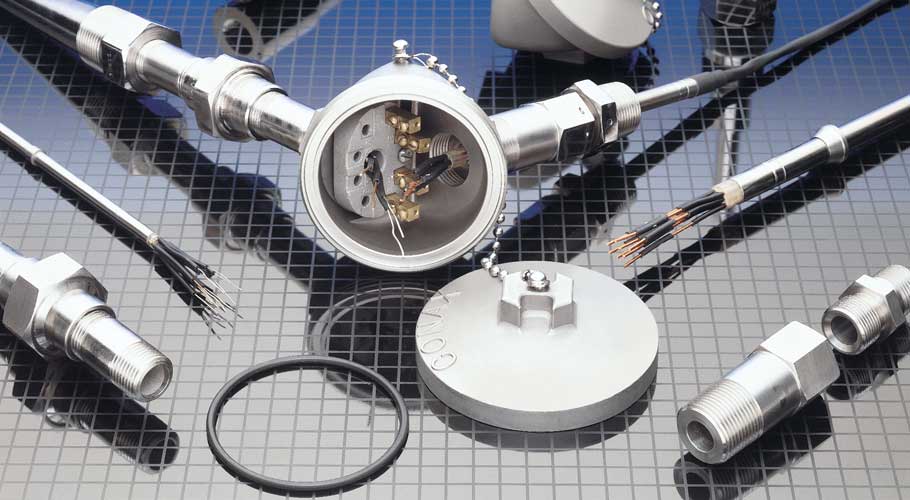

RTDs operate on the principle of the temperature-dependent electrical resistance of pure metals. RTDs are typically made by winding a thin wire made of platinum, copper, or nickel around an insulating core. As the temperature changes, the wire’s electrical resistance changes proportionally, allowing the measurement of temperature. RTDs have a positive temperature coefficient of resistance, which means that the resistance of the wire increases with an increase in temperature.

Types of RTDs:

The most commonly used RTDs are platinum RTDs, copper RTDs, and nickel RTDs. Platinum is the most stable and reliable material for RTDs, with a higher operating temperature range compared to copper and nickel. Copper RTDs are less expensive and have a smaller temperature range, while nickel RTDs are less accurate and stable.

Advantages of RTDs:

RTDs offer several advantages over other temperature sensors, including:

High accuracy and repeatability

A wide temperature range

High linearity

Minimal drift over time

Excellent stability and reliability

Longer lifespan compared to other sensors

Applications of RTDs:

RTDs are widely used in many industrial processes, including chemical processing, power generation, food processing, and HVAC control systems. RTDs are used in applications where high accuracy and repeatability are required, such as in laboratory equipment like incubators, ovens, and refrigerators. RTDs are also used in the automotive industry for engine temperature monitoring and in industrial heating systems.

In conclusion, RTDs are essential temperature sensors used in various industrial processes for temperature measurement. RTDs offer high accuracy, repeatability, linearity, stability, and reliability, making them a popular choice for temperature measurement. PT100 and PT1000 platinum RTDs are the most commonly used RTDs, although copper and nickel RTDs are also available. RTDs are used in various applications, including chemical processing, power generation, food processing, HVAC control systems, and automotive industries, due to their high accuracy and reliability.