In industrial applications, measuring force or weight is crucial for production efficiency and quality control. Load cells are transducers that convert force into an electrical signal, which is then measured and processed by an electronic instrument. There are different types of load cells, and each type has its own advantages and disadvantages depending on the application requirements. This article will discuss different types of load cells and their applications.

Types of Load Cells:

There are different types of load cells, including:

Strain Gauge Load Cells:

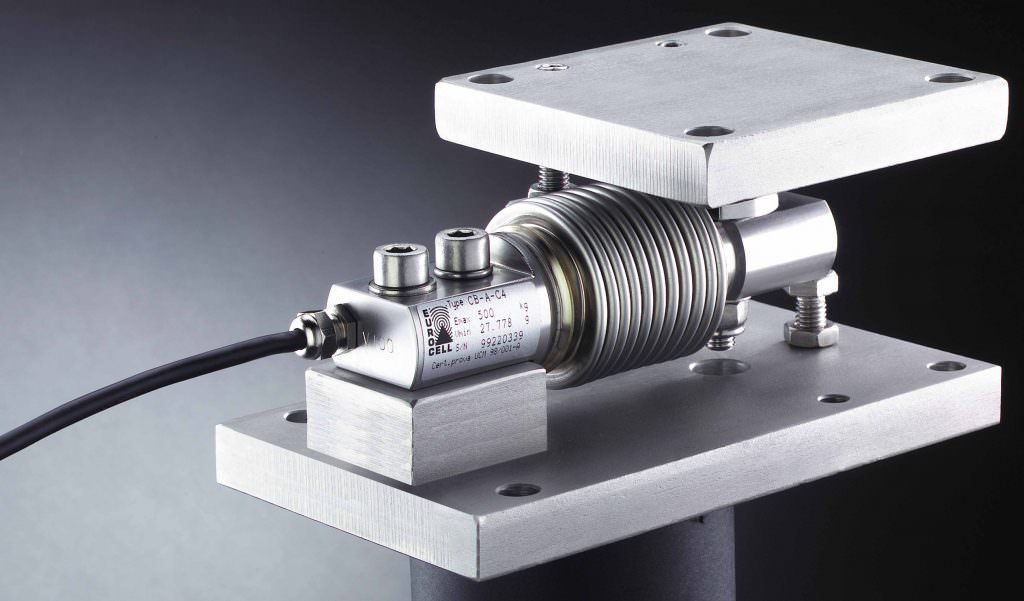

Strain gauge load cells are the most common type of load cells, and they operate on the principle of resistance change due to deformation. These load cells consist of a metal sensing element, which deforms when subjected to force or weight, resulting in a change in resistance. The change in resistance is then measured and converted into an electrical signal. Strain gauge load cells are commonly used in general-purpose applications due to their cost-effectiveness, high accuracy, and reliability.

Hydraulic Load Cells:

Hydraulic load cells operate on the principle of Pascal’s law, which states that the pressure applied to a confined fluid is transmitted equally in all directions. Hydraulic load cells consist of a piston and a diaphragm that is exposed to the force or weight. The force deforms the diaphragm, which causes a change in the hydraulic pressure that is measured and converted into an electrical signal. Hydraulic load cells are commonly used in applications where high capacity and durability are required, such as heavy machinery and truck scales.

Pneumatic Load Cells:

Pneumatic load cells operate on the principle of the deformation of a diaphragm due to air or gas pressure. Pneumatic load cells consist of two diaphragms, one exposed to the force or weight and the other connected to a reference pressure. The force deforms the diaphragm, which causes a change in pressure that is measured and converted into an electric signal. Pneumatic load cells are commonly used in applications where high accuracy and cleanliness are required, such as the food and pharmaceutical industries.

Capacitive Load Cells:

Capacitive load cells operate on the principle of a change in capacitance due to deformation. These load cells consist of two electrodes separated by a dielectric material, which deforms when subjected to a force or weight. The change in capacitance is then measured and converted into an electrical signal. Capacitive load cells are commonly used in applications where low capacity, high accuracy, and low deflection are required, such as compression testing and material hardness testing.

Applications of Load Cells:

Load cells are widely used in many applications that require the measurement of force or weight, including manufacturing, aerospace, automotive, and healthcare industries. Load cells are used in weighing equipment, such as truck scales, platform scales, and bench scales, as well as in testing and measurement equipment, such as tensile testing machines and compression testing machines. Load cells also play a vital role in force and stress analysis, as well as materials testing and quality control.

In conclusion, load cells are essential instruments used in many industrial applications for measuring force or weight. Strain gauge, hydraulic, pneumatic, and capacitive load cells are the most commonly used load cells, each with its own advantages and disadvantages. Load cells are widely used in various industries, including manufacturing, aerospace, automotive, and healthcare, due to their high accuracy, reliability, and durability.